I have now launched a Kickstarter project to gather backing to launch this product.

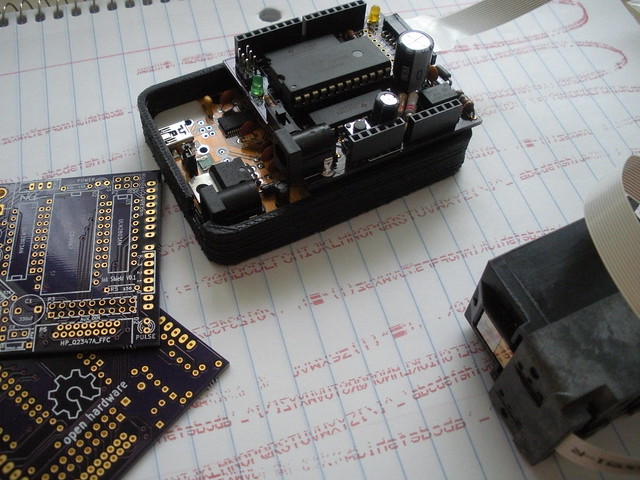

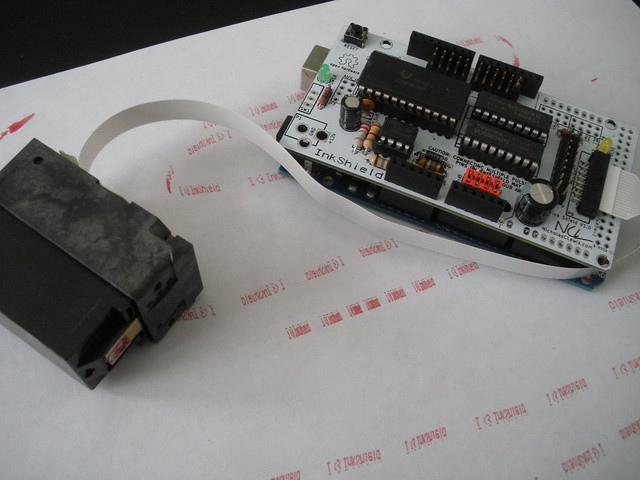

This shield allows you to connect a HP C6602 inkjet cartridge to your Arduino turning it into a 96dpi print platform. It only uses 5 pins which can be jumper selected to avoid other shields. It is designed with a Arduino Mega footprint but fully supports both the Arduino and the Arduino Mega. It is designed with all through-hole components to make assembly easy even for beginners.

All source code (both hardware and software) will be fully Open Source and released when the initial production run is completed.